process improvement AND QUALITY ASSURANCE

PROCESS IMPROVEMENT AND QUALITY ASSURANCE ARE FOUNDATIONAL VALUES AT CAB

Rely on CAB to drive down your total cost of ownership with our deep bench of experts.

40 Years of Excellence in Global Manufacturing and Engineering

For 40+ years, CAB Worldwide has led in global manufacturing, engineering, and distribution, setting excellence standards. With a worldwide presence, we adapt to evolving supply chain and market demands. Committed to long-term customer satisfaction, we build trusted relationships through exceptional support and ongoing quality improvement.

Our Key Differentiators

Manufacturing &

Design Expertise

Extensive expertise in varied manufacturing and industrial processes.

International &

Domestic Options

Global supply chain combined with Domestic Manufacturing

We Deliver

Our Strategic Just-in-Time Inventory Programs from U.S., Canada, and European warehouses ensure timely supply.

The Foundation of CAB

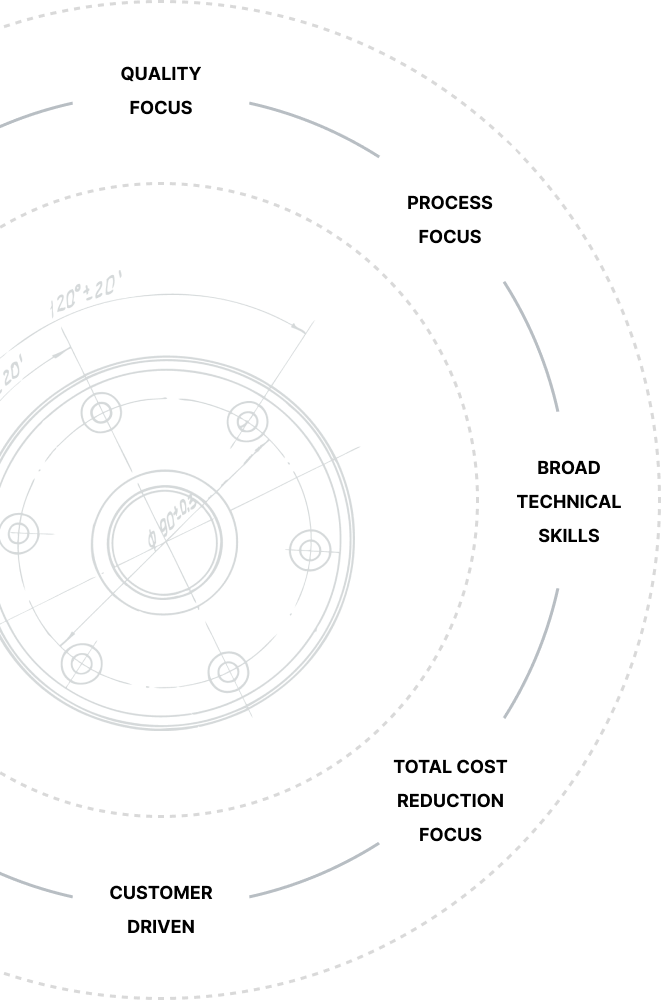

Technical Expertise and Commitment to Quality Create a Strong Foundation

A strong team of exceptional engineers in key processes and products has positioned CAB as a key contributor to our customers’ success. We firmly believe that providing the best service to our customers lies in meticulously controlled processes and an unwavering focus on detail.

Our engineers and our processes give our customers the resources and confidence to solve complex design and manufacturing problems and drive down costs. Our constant drive for improved process control and error proofing means repeatable high quality – further driving out cost. This commitment to quality extends to every employee and partner within the CAB network, all of whom stand firmly behind our promise to ensure YOUR success.

Rigorous Process Control and Relentless Pursuit of Quality

At CAB, our exceptional team of engineers excels in key process design and product development, making us a vital contributor to our customers’ success. Process Improvement and Quality Assurance are in our DNA.

Our engineers empower our customers to tackle complex manufacturing challenges, consistently delivering high-quality results while reducing costs. We continuously improve our processes to ensure repeatability and excellence. This dedication to quality extends to every member of the CAB network, including our employees and partners, all working together to support your success.

“At CAB Worldwide, we drive innovation and resilience by empowering our global teams to adapt, evolve, and challenge the status quo. Our commitment to excellence ensures we remain a trusted partner in delivering quality and value across industries.”

Terri Jondahl, CEO

deep worldwide expertise

With a top-tier team of foundry engineers, forging experts, machining experts, Six Sigma-trained quality specialists, and multilingual managers, representing over 500 years of experience CAB dominates the industrial castings and forgings markets. Operating globally in the US, Canada, Italy, India, and China, CAB excels in materials such as steel, iron, aluminum, stainless steel, and various alloys. Our precision is ensured by dedicated engineering and inspection teams both overseas and at our US facilities.

Transform Your Vision into Reality – Partner with Us for Precision, Quality, and Unmatched Excellence in Manufacturing Solutions